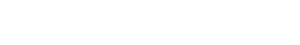

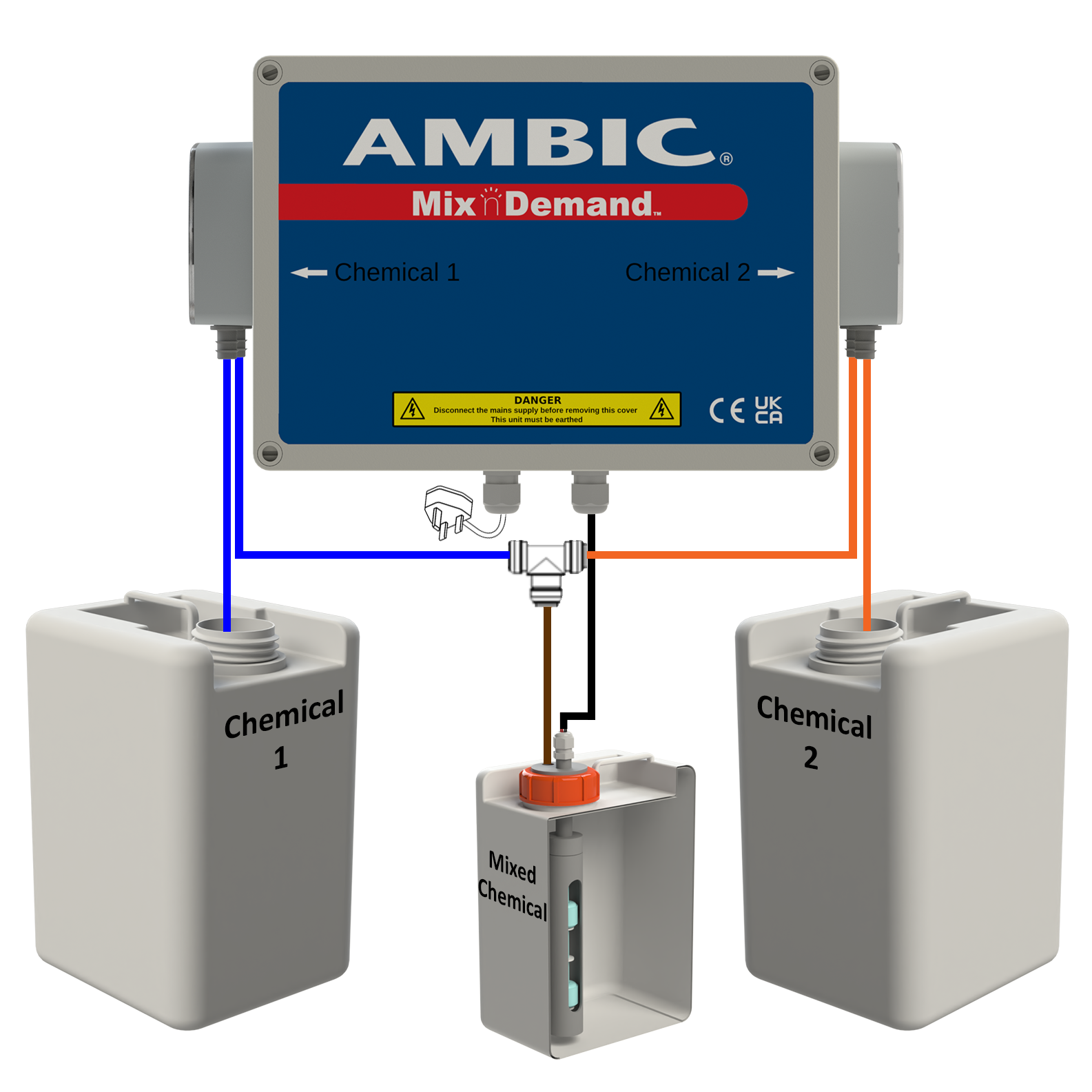

The Ambic Mix’n’Demand™ chemical dosing system mixes two-part teat sanitisation chemicals during milking so that a fresh mixture is always on hand when needed, without expensive chemicals being wasted at the end of milking.

This system is particularly intended for the growing demand to mix small batches of Chlorine Dioxide (which must be used within 24 hours, so must be mixed daily) and for other chemicals which may have a short shelf life once mixed. The system is suitable for use with spraying, dipping or foaming chemicals.

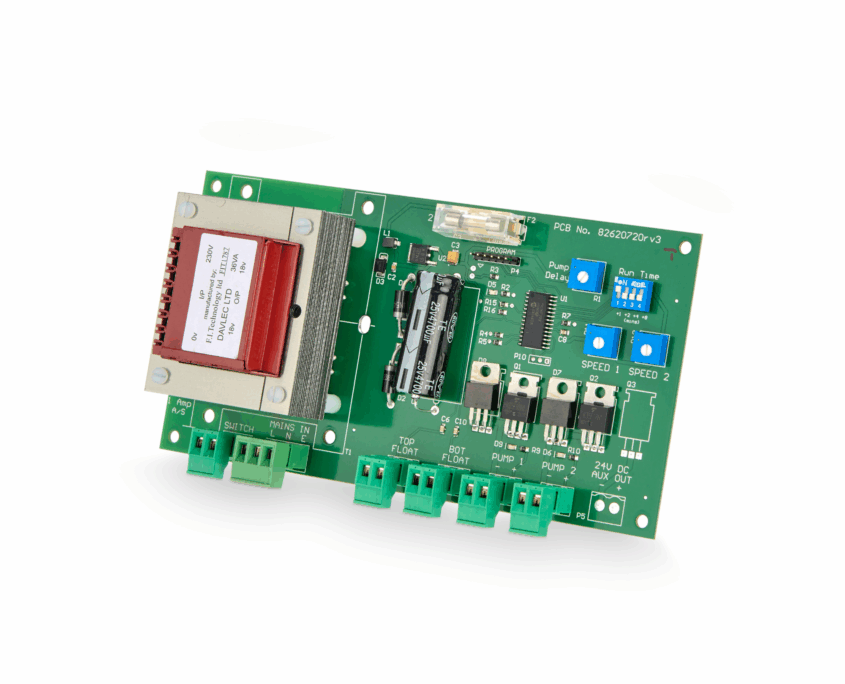

The Ambic Mix’n’Demand™ system is fitted with two peristaltic pumps with Speed control potentiometers to mix two chemicals. Dual Float switches control the output into the mixed chemical container. An optional vacuum switch automates switching the unit on and off in tandem with the milking system. A Time Delay feature is also available; it controls a delay of up to 15 minutes from when the lower float switch activates, to the start of pumping of the mixed chemical into the container.

If for any reason the mixed chemical activates the top float switch, both pumps will stop running immediately

Ordering information: Mix’n’Demand™ System

| Part No | Description |

|---|---|

| MDE/003-2LV | Mix’n’Demand system with 2 Low-Volume Pumps, Float switch assembly and the mixed chemical container. |

| MDE/001-2LV | Mix’n’Demand with 2 Low-Volume Pumps – power unit |

Ordering information: Mix’n’Demand™ System Spare Parts

| Part No | Description |

|---|---|

| ALP/101-SA625-ATS | Peristaltic Santoprene tube with ATS connectors |

| ALP/115 | Peristaltic pump tube lubricant |

| ALP/102 | Spring loaded spinner assembly |

| ALP/203-C | Low and Medium-Volume Pump Block and Cover with Screws |

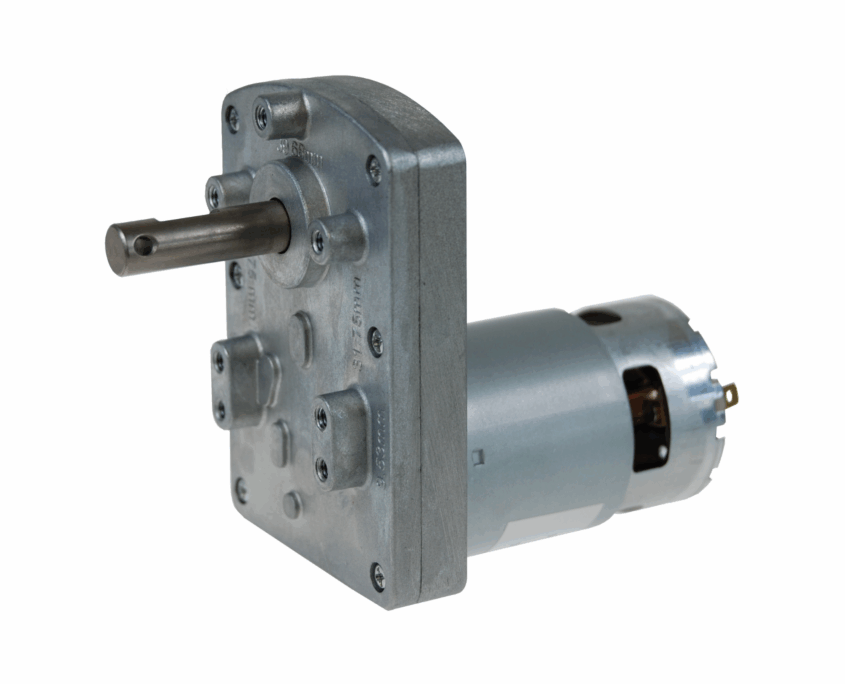

| ALP/100-24-188 | 24V DC Motor and Gear Assembly |

| MDE/004 | Mix’n’Demand PCB |

| ATS/412-NR | Non Return Valve Intake Filter |

| MDE/006 | Float Switch Assembly incl. cap |